|

CALL NOW! toll-free M-F 8-5 Central

Dallas

Fort Worth/Arlington Areas

Hillsboro/Waco Areas

Sherman/Greenville/Paris

Denton/North Texas Areas

Dallas Areas Email our Sales Team

|

SolarBrite™ Light Emitting Diode (LED) TechnologyA light-emitting diode (LED) is a semiconductor device that emits incoherent monochromatic light when electrically biased in the forward direction. This effect is a form of electroluminescence. The color depends on the semiconducting material used, and can be near-ultraviolet, visible or infrared. A LED is a special type of semiconductor diode. Like a normal diode, it consists of a chip of semiconducting material impregnated, or doped, with impurities to create a structure called a pn junction. Charge-carriers (electrons and holes) are created by an electric current passing through the junction, and release energy in the form of photons as they recombine. The wavelength of the light, and therefore its color, depends on the band gap energy of the materials forming the pn junction. A normal diode, typically made of silicon or germanium, emits invisible far-infrared light, but the materials used for a LED have band gap energies corresponding to near-infrared, visible or near-ultraviolet light. Unlike incandescent bulbs, which can operate with either AC or DC, LEDs require a DC supply of the correct polarity. When the voltage across the pn junction is in the correct direction, a significant current flows and the device is said to be forward biased. The voltage across the LED in this case is fixed for a given LED and is proportional to the energy of the emitted photons. If the voltage is of the wrong polarity, the device is said to be reverse biased, very little current flows, and no light is emitted.

Blue LEDs became available in the late 1990s. They can be added to existing red and green LEDs to produce white light. Most "white" LEDs in production today use a blue LED chip covered by a scintillate coating made of Zinc solenoid (ZnSe). The LED chip emits blue light, part of which is converted to yellow by the ZnSe. This mixture of blue and yellow light creates the impression of white - hence the bluish or yellowish tint that these diodes usually exhibit. The most recent innovation in LED technology is a device that can emit ultraviolet light. When ultraviolet light illuminates certain materials, these materials will fluoresce or give off visible light. White light LEDs have been produced by building ultraviolet elements inside material that fluoresces to produce white light.The semiconducting chip is encased in a solid plastic lens, which is much tougher than the glass envelope of a traditional light bulb or tube. The plastic may be colored, but this is only for cosmetic reasons and does not affect the color of the light emitted. Most typical LEDs are designed to operate with no more than 30-60 millewatts of electrical power. In 2002, 5 watt LEDs became available with efficiencies of 18-22 lumens per watt.SMD (Surface Mounted Device) LEDs have been created that combine RGB (Red, Green, Blue - which can make White) color sources in one LED. This allows the display matrix, pitch, to be much closer. They are very expensive, but more importantly do not have the light output for outdoor use. Manufacturers currently brag that they can produce 4-6,000 nits. We are patiently watching this development. Incidentally, a “nit” is an older term describing a luminance factor. It basically refers to “…the illumination of a 1 square meter surface by the light of one candle shining on it.” It pertains to TVs and cell phone screens, not signs with exposed LED lighting. It has no ANSI or International System of Units (SI) fixed method of determination, such as from how far away it is measured, so it has no scientific meaning, or comparative value. It is a marketing term. The brightness of SolarBrite™ LEDs is turned down when they are too bright. Click "here" for more details on LED sign brightness. Many companies manufacture LEDs. There are over 5,000 varied LEDs available, and they vary greatly as to brightness, nits, lux, light-dispersal (viewing) angle, useful LIFETIME*, and LIFETIME*. Some are very cheap, some are quite expensive. Sunburst Displays'™ Sunburst Displays™ only use SolarBrite™ LEDs that are rated to retain 80% of their brightness for 60,000+ hours. It will take much longer than 100,000 hours before SolarBrite™ LEDs dim to 50% of their original brightness – what the industry calls “lifetime.” These are the most expensive, but highest value, conventional LEDs. Our selection of LEDs is what makes our signs brighter, and last longer. A SolarBrite™ LED incorporates a new kind of chip, different from all other LEDs. Sunburst Displays™ is an industry leader in the implementation of new technology in advertising. SolarBrite™ LEDs utilize military specification coatings on the circuit boards the LEDs are attached to, preventing corrosion and electrical problems. LEDs are also affected by voltage. For instance, an LED will also burn nearly 100% brighter if you double the power feeding it. The LED will last about 1/6 as long, however, making this alternative quite expensive in total cost. We power our SolarBrite™ LEDs properly. What is Binning?ALL LED lamp production is binned, grouped with LEDs with similar properties, 3 different ways: color, flux (brightness), and forward voltage (the minimum voltage the LED will operate at, using a specified minimum operating current.) All 3 vary in even a single wafer’s production, so binning is critical. LED “binning” is controlled by an ANSI minimum standard: ANSI C78 377A. SolarBrite™ LEDs are binned to much tighter standards, however, which is allowed. If a competitor BRAGS that their product is binned, they are probably warning you that they will not be able to match color and brightness later, when replacement parts are needed, because their sign’s individual LED color and flux is not adjustable. The SolarBrite™ LongLife™ System

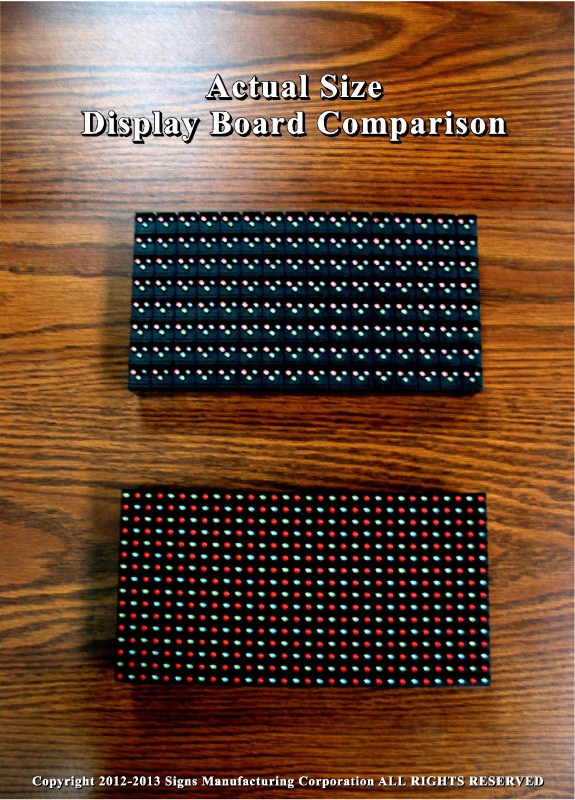

Remember that each LED consumes differing amounts of electricity to operate, which is partially why they were binned (above.) Forward voltage even varies based on the color of light produced by an LED. We obviously must supply enough voltage to meet the highest forward voltage requirement. Therefore each resistor is also sized to consume the potential over-supply of voltage from the power source feeding all the LEDs. Done properly, this double-protection lengthens the life of LEDs (reduces heat-generation.) This is a critical part of the SolarBrite™ LongLife™ System. Size MattersNotice the size of the LEDs in the photograph below. Sunburst Displays™ Balanced Array™ (the bottom LED board) uses LEDs that are 250% larger in area than virtually any LEDs used by manufacturers that still manufacture pixel cluster displays. Our purpose-built LED is oval, focusing most of the light forward, to the sides, and down. No reason to waste energy shining light on the glare shield above the LED. These larger oval LEDs result in brighter signs with more “light-fill” in every image.

|

|

214-339-2227 254-582-7446

817-861-1234

903-561-5959

940-365-3433

972-850-3300 877-SINCE-79

TOLL-FREE |

||

Conventional LEDs are made of inorganic minerals such as:

Conventional LEDs are made of inorganic minerals such as: An operating LED is a direct electrical short; it will consume all the current fed to it; destroying both it and its power source. However, an LED has a rather-constant voltage drop when operating. A current-limiting resistor is placed in-line with LEDs to restrict the forward current.

An operating LED is a direct electrical short; it will consume all the current fed to it; destroying both it and its power source. However, an LED has a rather-constant voltage drop when operating. A current-limiting resistor is placed in-line with LEDs to restrict the forward current.

FOR ORDERING OR ASSISTANCE CALL:

FOR ORDERING OR ASSISTANCE CALL: